How is Edgebanding Applied?

In most professional production lines, edges are applied using an edgebander machine. The panel is placed into the machine, adhesive is applied, and the edging strip is pressed firmly onto the surface under controlled pressure.

Once attached, excess material at the top, bottom and ends is trimmed away, leaving a flush, consistent finish. Depending on the model, further processes can be added, such as corner rounding, scraping for a cleaner edge, and buffing or polishing to give the surface a seamless appearance.

Feed speeds can vary, with industrial woodworking machinery often running between 10 and 20 metres per minute, making edgebanders a key part of high-volume panel processing.

What Materials are Used for Edgebanding?

Edgebander machines are designed to work with a variety of edging materials, including PVC, ABS, melamine, veneer, solid wood and acrylic. The right choice depends on the application and the look required, whether it is a cost-effective finish for everyday use or a high-end result for bespoke furniture.

At ILEX Machinery, we also provide the machinery and consumables that make the process reliable, including glue systems and adhesives suitable for different applications.

Choosing an Edgebander Machine

There are many types of edgebander machines available, from compact models with smaller output to fully automated systems for continuous production.

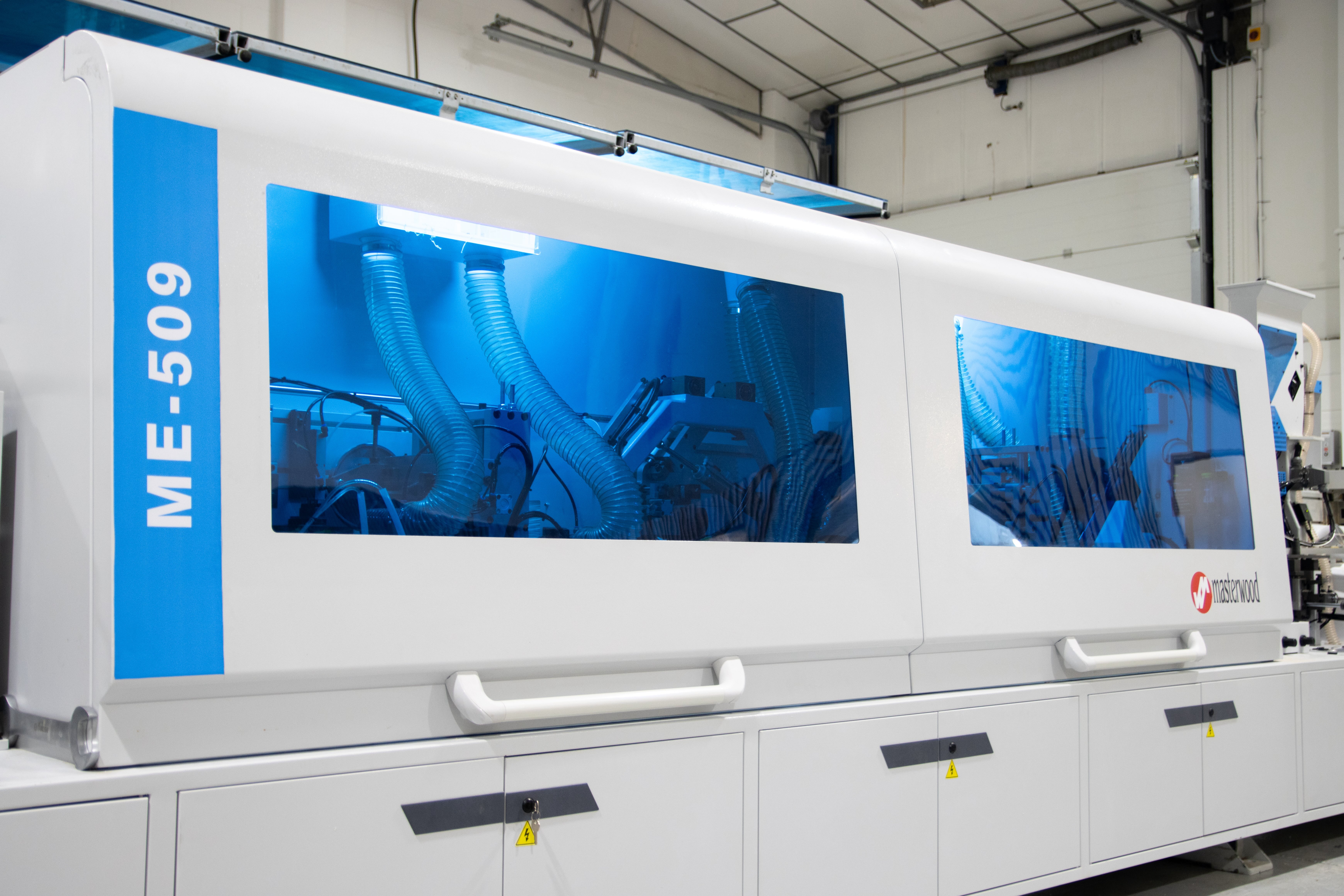

At ILEX Machinery, we work with trusted manufacturers including Masterwood and Casadei Busellato to provide machines that suit a wide range of requirements. For businesses producing at lower volumes, smaller machines are available that handle the essentials with accuracy.

For larger operations, more advanced machines are available with features such as pre-milling, multiple trimming units, corner rounding and polishing stations. These options help increase speed, reduce manual intervention and deliver consistent quality.

Double-Sided Edgebanders

A key area of expertise for ILEX Machinery is in double-sided edgebanders. With decades of experience working with these machines, we can provide tailored advice on how they fit into high-volume production lines. Double-sided edgebanders process both edges of a panel in a single pass, significantly reducing handling time and increasing throughput without compromising quality. This makes them an ideal choice for manufacturers working to time-critical schedules or operating fully automated lines.

When choosing a machine, it is important to focus on how the machine will fit into your production line, the types of panels you are processing, and the level of finish you need.

Independent advice from ILEX Machinery ensures you have the right choice for your setup.

Edgebander Maintenance

Like all woodworking machinery, an edgebander requires regular maintenance to stay reliable.

Glue systems should be kept clean, buffer wheels and cutters checked regularly and remove dust and debris from the working area.

Scheduled machine maintenance carried out by experienced engineers ensures alignment is correct, settings are accurate, and parts are replaced when needed.

Proactive maintenance is the most effective way to reduce downtime and avoid unexpected disruption. It also ensures the machine continues to deliver precise, high-quality edges.

Benefits of Good Edgebanding

Although it is often the last stage in production, edgebanding makes a significant difference to the quality of a product. It strengthens panels, improves appearance, supports hygiene, and gives customers confidence in the end result.

For panel processing businesses, investing in a reliable edgebander machine and keeping it maintained through regular servicing helps minimise downtime, reduce waste and ensure consistent output.

How ILEX Machinery Can Help

At ILEX Machinery we supply and support a carefully selected range of edgebander machines, along with consumables such as hot melt adhesives. Our role is to provide independent, practical advice to help you choose a machine that suits your production needs and to support you with ongoing maintenance and technical help.

We work with business and manufacturers across the UK, from small joinery shops to large industrial facilities, ensuring they have the right woodworking machinery in place to deliver quality and efficiency.

If you are considering adding an edgebander to your manufacturing line or upgrading your existing machinery, speak to our team.

We will provide advice based on your requirements and help you find a solution that works for your business, give the team a call 07743 625 998 or email sales@ilexmachinery.co.uk.

Or view our available Edgebanders.