- Home

- Machines

- New Machines

-

Masterwood ME-508

Masterwood ME-508

Automatic edgebanding

Masterwood ME-508 Edgebander

The Masterwood ME-508 Edgebander is designed for precision, efficiency, and reliability.

With advanced automation and excellent edge application, it delivers a perfect finish every time, making it the perfect choice for high-quality production.

Key Information about the Masterwood ME-508

Machine Specifications

Machine Dimension |

5346 x 830 x 1960 mm |

Working speed |

15-23 m/min |

Min. panel size |

120 x 90 mm |

Panel thickness |

10-60mm |

Edge thickness |

0.4-3mm |

What's Included

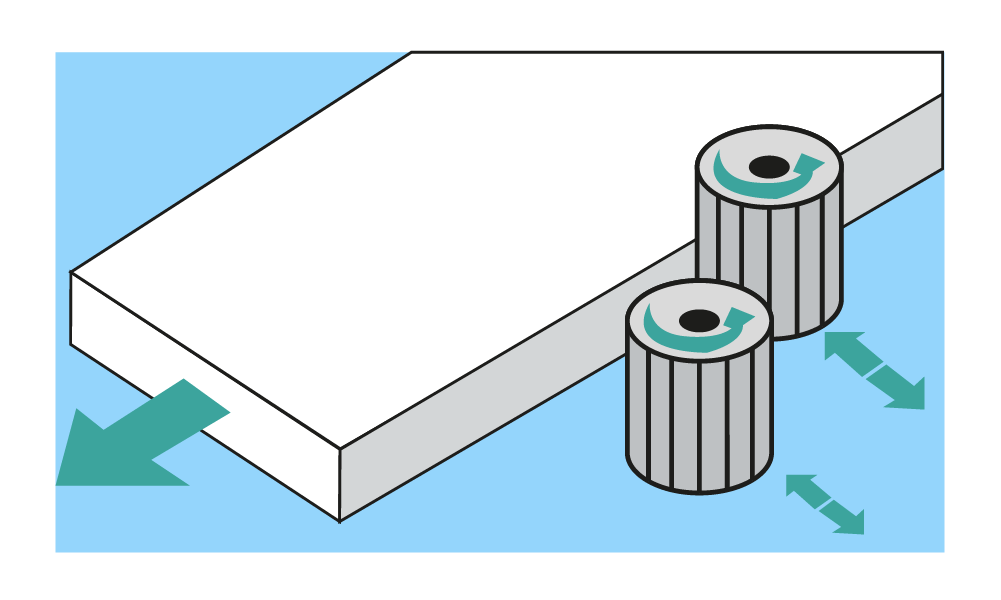

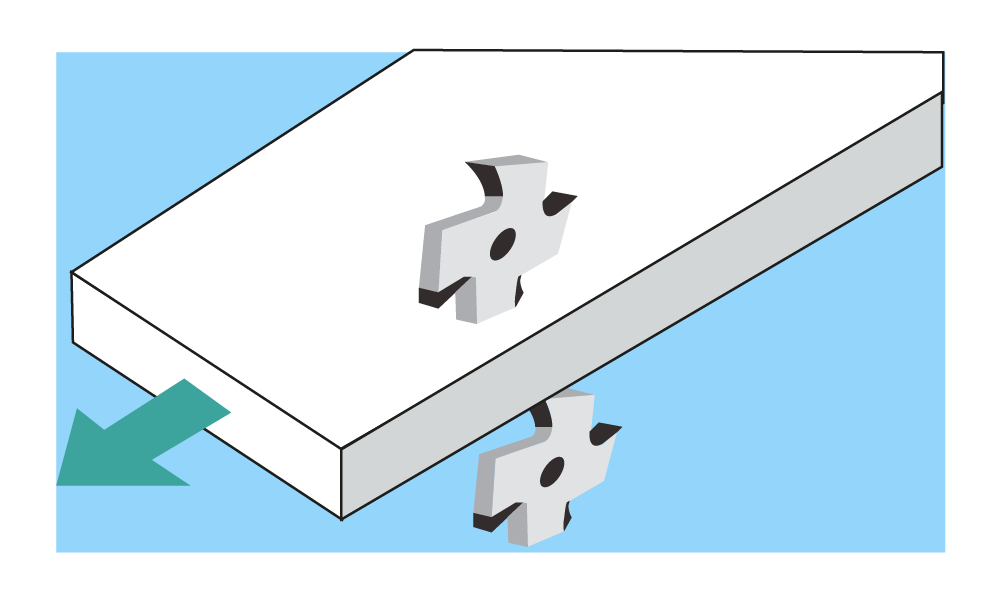

Pre Milling

The rectifier allows the machine to perfectly square and finish the panel in case of chips or not straight surfaces

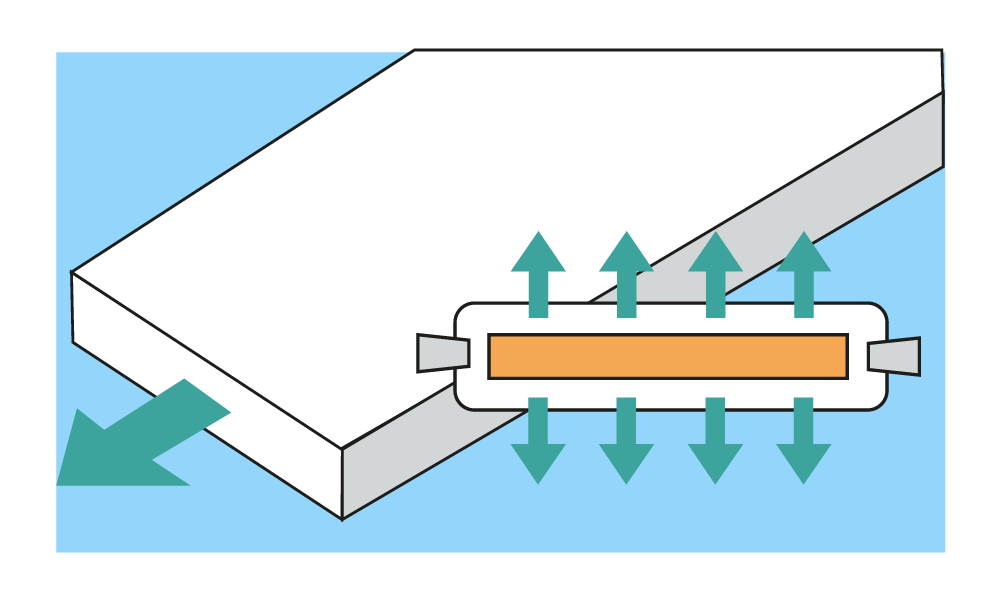

Pre Heating Lamp

The preheat lamp helps the panel to warm up when ambient temperatures are low, it also removes humidity from the panel. This is essential for an excellent sealing of the glue on the panel and on the edge to be glued.

Glue Scraping

The glue scraper unit is essential for removing any glue residues from the panel surface. Thanks to these copiers, it can also work with panels that hinge holes.

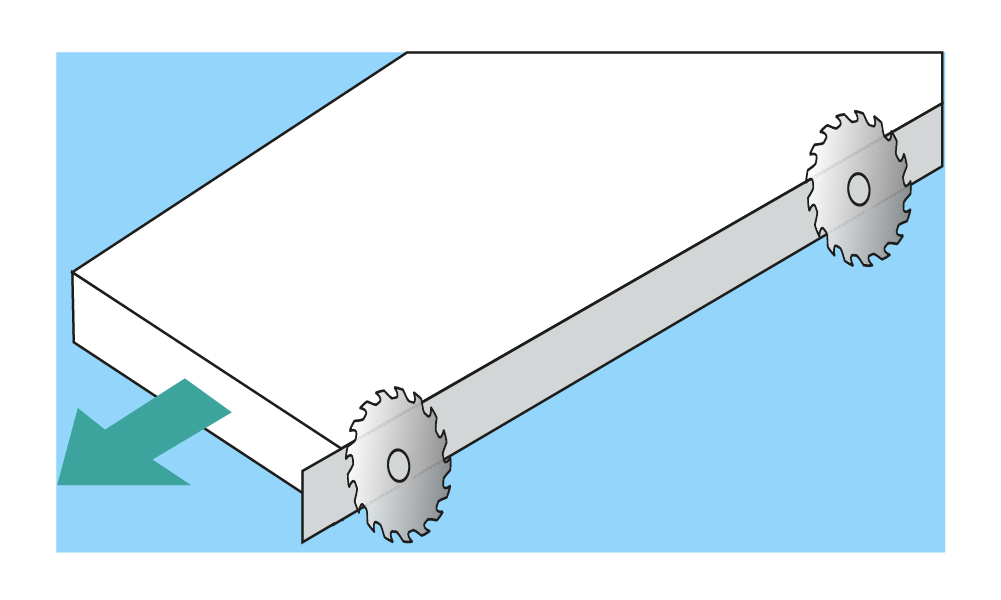

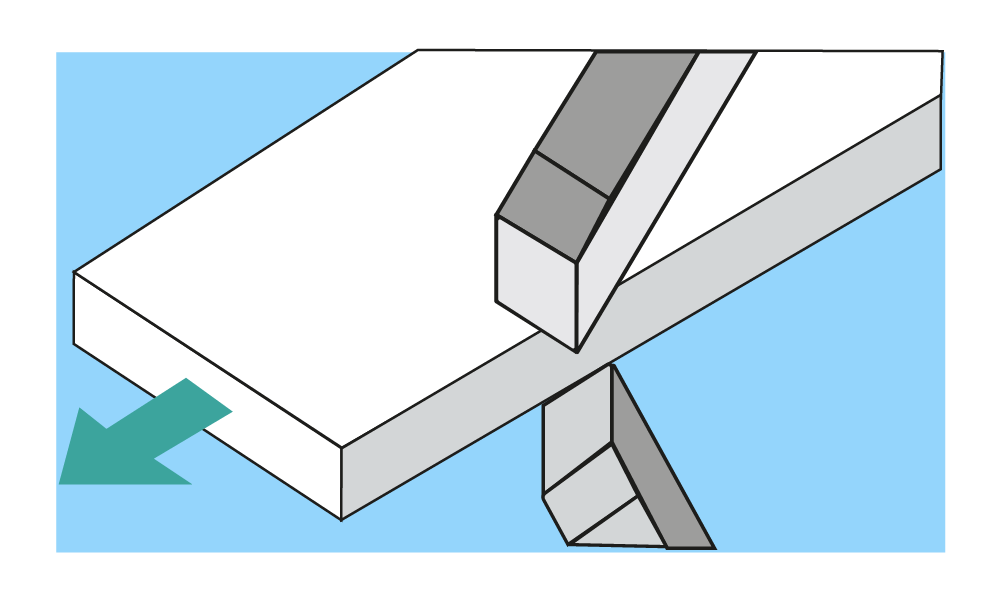

End Cutting

The two headers trim the excess edge in front of and behind the panel. The cutting units move precisely on two prismatic linear guides equipped with automatic lubrication.

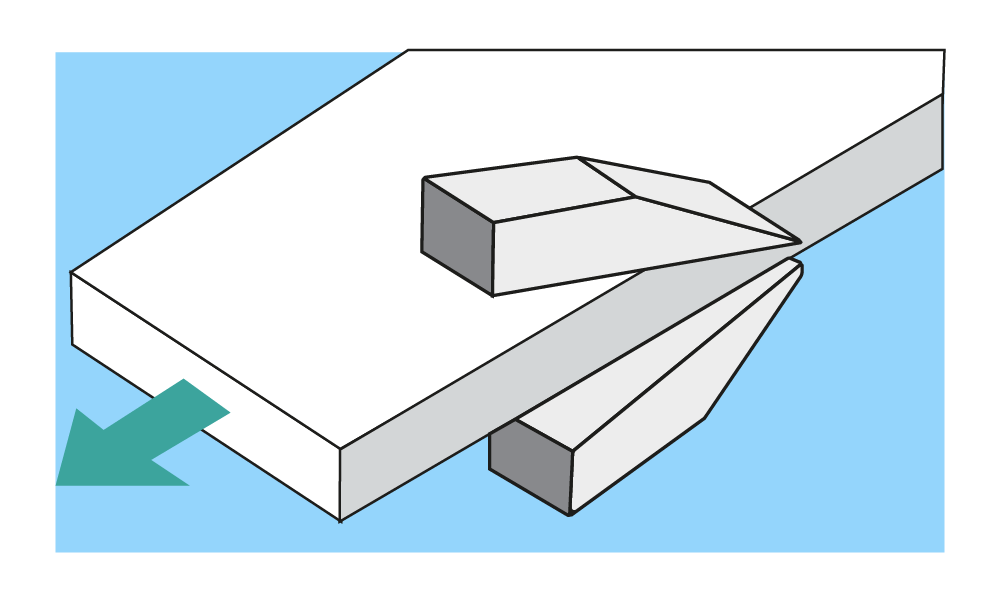

Fine Trim

The top and bottom edge trimming unit removes excess edge to help subsequent units achieve an excellent edge finish. The group is equipped with two pneumatic positions.

Edge Scraping

The edge scraper unit rounds the edge according to the required radius, works with two large copiers which allow the unit to work at high speeds. The group is equipped with two pneumatic positioning.

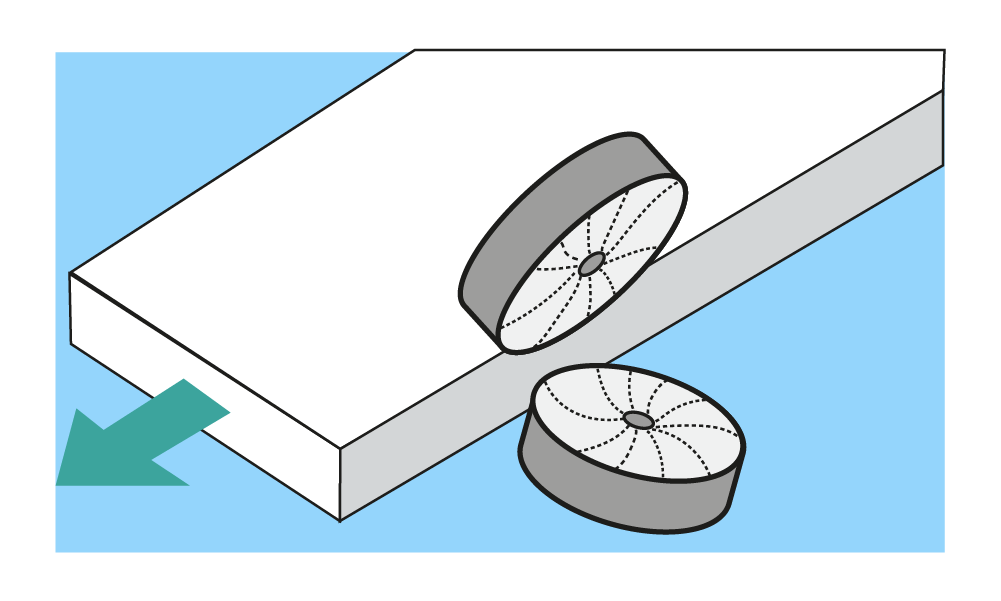

Buffing

The buffing unit is a device with two rotating brushes for cleaning the applied edges

Gallery

Finance Available

Finance Available on All Machines

Finance is available on all our machinery, subject to status. Spread the cost with varying monthly payment options to allow you to have flexibility on paying for your new asset. Please get in touch to speak to a representative.